My Home - My Hobby

This page shows the construction process of my home and some unique features that I installed during its construction.

This page is still under construction. Descriptive text and more photos will be added soon!

//////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

|

|

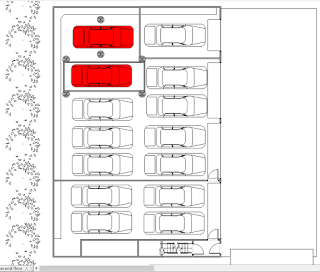

| When I designed my garage, I was planning for the ability to house all 1976 Buick Electra. One of the Longest Buicks ever made. The barn can actually house 3 normal vehicles deep. |

The second floor was originally going to be storage for the garage, but I took a small section and made it into livable space. |

|

|

| Experiencing the Ice Storm from 1991 and Losing Power for over two weeks, I never wanted to experience it again. Before anything else was created, we brought up our 25kW (35kW peak power) automatic Backup Generator. |

Then our driveway was formed. A highway landscape fabric was used to prevent driveway gravel from being lost into the dirt below. |

|

|

|

Poles started being erected. To provide a scale to the project, I stand next to the center ridge pole of the end wall.

|

Until more interesting photos come about, I will let the photos speak for themselves.

|

|

. |

. |

|

. |

. |

|

. |

. |

| . |

. |

|

. |

. |

| The west wall provided some shade in the setting summer sun. |

My Great Uncle enjoyed construction and watching the progress I would make on the barn. My Mom and Dad are around to lend a hand and support during construction. |

|

|

|

| Here I am, digging for the future waste water exit and Utility entrance. |

. |

.

|

. |

| . |

. |

|

|

|

With most of the garage closed in, I prepared for the heating system, exhaust system, anchors, and other provisions. Styrofoam and plastic formed a vapor barrier, and rebar mesh provided a place to anchor radiant heat tube and support for the fiber-reinforced concrete.

|

Anchors were set for tire changing machines and areas were marked so not to damage the radiant tube.

|

|

|

|

The areas were marked for the placement of the future car lifts. Those tubes sticking up are for chain anchor storage (used to straighten bent car frames and other anchors) and exhaust (carbon monoxide) evacuation. The exhaust evacuation tubes allows me to connect my cars with a hose and run vehicles with garage doors down and not asphyxiate the occupants of the garage.

|

The floor was so large, that we needed to do it in two pours. The seam is at the center of the garage providing a natural stress relief.

|

|

. |

|

| . |

. |

|

|

|

| . |

. |

|

|

| As you glance to the west wall, you can see the radiant tubes ready to connect to the future heating system. |

With the concrete in, the exhaust tubes were trimmed fluck to floor level. |

|

|

|

| .Yes that is me almost 20 feet off of the ground! |

. |

|

|

| .My great uncle in the Back-hoe, while my dad and I unpack the lifts. |

. |

|

|

|

. |

. |

|

|

| . |

. |

|

|

|

| Raising the support beams to hold the second floor... |

. |

|

|

|

| . |

. |

|

|

|

| . |

. |

|

|

|

| . |

. |

|

|

|

| . |

. |

|

|

|

| Floor Joists were placed every foot on center to handle a heavier load capacity. |

My design exceeded both live load and dead load limit ratings.

|

|

|

. |

| The lift works well as an elevator, allowing heavier loads to be delivered to the second floor without difficulty. |

. |

| . |

. |

| . |

. |

| . |

. |

| . |

. |

I would show more construction photos, however, for security reasons more details will not be posted at this time. (I guess you will have to come and visit!)